Technical article

Types and characteristics of inductors

There are many kinds of inductors, some of which are called by function, such as "anti-current coil" and "ignition coil" etc. Some are expressed by shape like "chip inductor". An inductor will have many names depending on its usage, which can easily cause confusion.

Next, we will introduce inductors from different pointcuts.

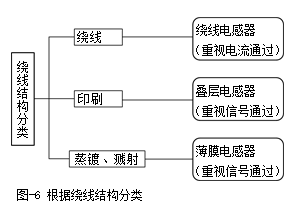

Classification based on winding structure

Wound inductor

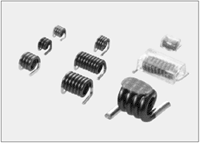

About coils, the most familiar thing is spring inductors.

ÕÕƬ-1¡¡Spring inductor

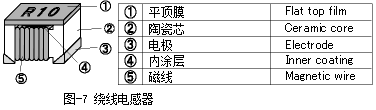

Such an inductor is basically a copper wire with an insulating film, that is, a magnetic wire, a coil-like spring-like spiral shape, a type wound around a plastic bobbin, and a type directly wound around a molded ferrite core.£¨Fig. 7£©

Fi-8¡¡Rectangular magnetic wire effect

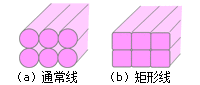

In order to meet the demand for miniaturization and thinning, such inductors have developed many kinds of winding structures. There is no shortage of types that use rectangular magnet lines instead of circles. (Fig. 8) In this way, the gap of the winding portion is eliminated. When the number of turns is the same, the cross-sectional area of the copper wire is increased, the DC resistance is reduced, and the copper loss is also reduced. This makes it possible to produce a highly efficient inductor.

For the same reason, the use of copper plates instead of magnetic wires has also been put into practical use.

Laminated inductor

Compared with energy efficiency, inductors for high-frequency circuits pay more attention to miniaturization and high-frequency characteristics. Nowadays, the idea of discarding "winding" has appeared, and conductors of conductor metal are printed on the sheets and substrates.

A fraction of a circle of inductor is printed on a green sheet that is stretched into flakes from ferrite and ceramic materials. Overlapping multiple layers is the inductor. With the thinning of green sheets, fine printing techniques, and advances in the technology of using via-holes, it is possible to fabricate small, high-inductance inductors. (Fig.9)

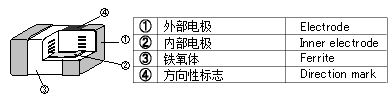

Fig-9¡¡Laminated inductor

Thin film inductor

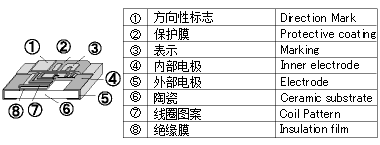

Corresponding to a laminated inductor printed by a screen printing method, an inductor having a coil pattern is formed by using a metal film having a thinner printing than a printing method using a sputtering degree and an evaporation technique, and is called a thin film inductor. Provides small, high-precision inductors through the use of semiconductor manufacturing technology. (Fig. 10)

Fig-10¡¡Thin film inductor

Classified according to placement

There are lead type inductors for surface mount and surface mount type (chip inductors).

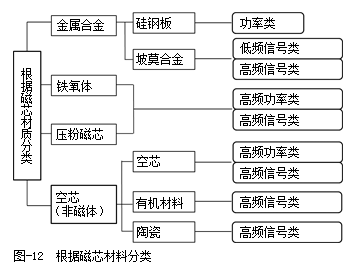

According to the core material classification

Silicon steel plate

Materials that are good at use in the low frequency band are widely used in power transformers, choke coils, etc. in the commercial frequency band (50/60 Hz). Adding a few percent of iron to iron can increase magnetic permeability and reduce aging. This material is cold-rolled to form a plate having a thickness of about 0.05 to 0.5 mm, and then pressed into an E-type I, and then several tens of sheets are used in an overlapping manner.

In order to prevent the loss caused by the eddy current, the surface of the core should be insulated one by one. The higher the frequency, the thinner the steel plate used.

Permalloy

A high magnetic permeability material made of nickel added to iron is called permalloy. By adjusting the nickel content, the initial magnetic permeability and the saturation magnetic flux density change, and thus it is suitable for a low-frequency signal transformer, a choke coil, and the like.

Powder core

It is pressed from a fine particle powder containing molybdenum as a main component, and its magnetic resistance is higher than that of a bismuth steel plate, so that the loss due to eddy current can be reduced. Suitable for high-frequency smoothing coils of power line filters and switching power supplies.

Ferrite core

Wide range of high permeability materials for high frequency applications. The main component, iron oxide (Fe2O2), is mixed with a metal compound such as manganese, magnesium, nickel, zinc, etc., and is sintered at a high temperature. Representative ferrites include Mn-Zns and Ni-Zns.

Air core

An inductor that does not use a magnet as a core material is called a hollow inductor. The core material is hollow (air), and the core material is a wound inductor using a non-magnetic material such as alumina, a laminated inductor in which a non-magnetic material sheet is stacked, a thin film inductor using a non-magnetic material substrate, etc., all of which are hollow inductors. Device. It is called a hollow inductor because there is no such thing as a magnet core (= empty).