|

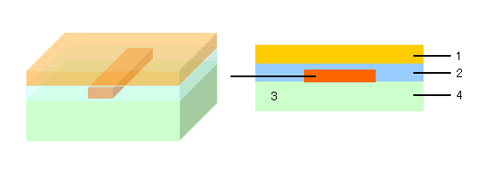

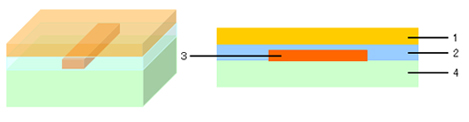

Single-sided FPC

Features

Basic structure:

Application:

|

|

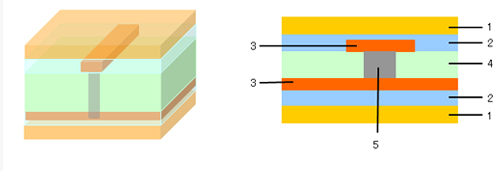

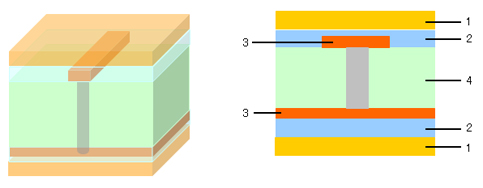

Double-sided FPC

Features:

Basic structure:

Application:

|

|

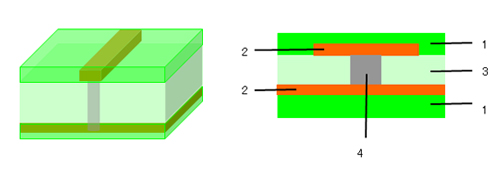

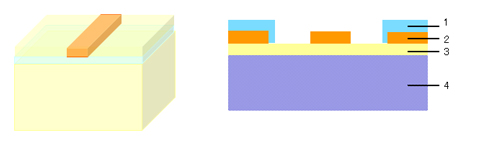

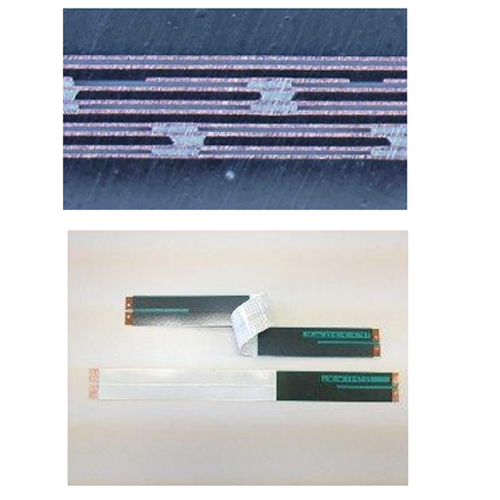

High-flex FPC

Features:

【Flexing characteristics】 At least 10 million times at 70°C. Evaluation conditions: Temperature: 70°C; clearance: 10 mm (R=5); stroke: 80±1 mm, speed: 35 times/minute

Basic structure:

Application:

|

|

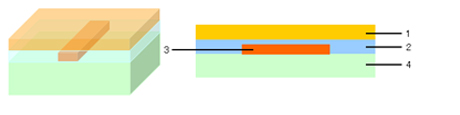

Low-loss FPC

Features:

Basic structure:

Application:

|

|

Long FPC

Features:

Basic structure:

Application:

|

|

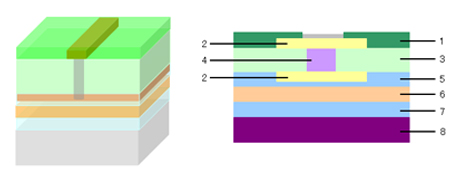

Thin multilayer substrate

Features:

Application:

|

|

Transparent FPC

Features:

Basic structure:

Application:

|

|

Component-mounting FPC

Features:

Basic structure:

|